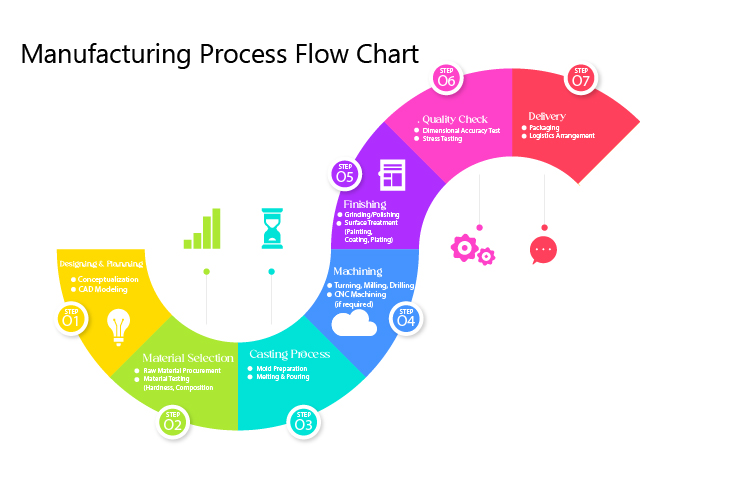

Manufacturing Process Flow Chart

Manufacturing Process

At DURGA ENGINEERING WORKS, we focus on delivering high-quality machinery and precision engineered products with simplicity and efficiency. Our streamlined manufacturing process ensures that every product meets the needs of our clients in industries like automobile, agriculture, mining and aerospace. Here’s an overview of how we work

Design and Planning

We start by understanding your requirements. Our team creates designs and plans using basic engineering tools to ensure the product meets your needs before moving to production.

Material Selection

We prioritize using high-quality materials like Mild Steel (MS) and Stainless Steel (SS) to ensure durability and performance. Our materials are sourced from trusted suppliers and undergo rigorous testing for strength, composition and surface quality. We select materials based on the product’s application,

functionality and industry standards. This careful selection process guarantees that every product we deliver meets the highest quality and reliability standards.

Casting

For parts that need casting, we use simple and effective methods to shape metal into the desired forms. This includes creating molds, melting metal, pouring it into molds and finishing the cast parts.

Machining

Our machining process is the core of what we do. We use standard machines like:

- CNC Machines: For precise cutting and shaping.

- VMC Machines: For milling and drilling operations.

- Drilling and Turning Machines: For creating holes and shaping components.

Finishing

After machining, we clean and finish the products to ensure they look good and perform well. This includes grinding, polishing and basic surface treatments.

Quality Check

Every product goes through a simple but thorough quality check. We measure dimensions, check for defects and test functionality to ensure it meets our standards.

Delivery

Once the product is ready, we pack it securely and deliver it to you on time.